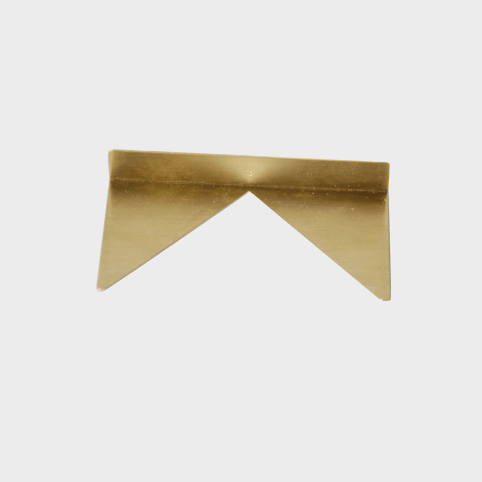

This week I want to show you how our brass corner cutters work, they are so easy to use and give such a great result. Here is a little video.

I know when I was learning I used to get so nervous cutting my corners with my big old bookbinding shears. Of course, the fear was that you would cut too close and have to start your case all over again, wasting all that board and cloth. So, what you would inevitably end up doing was cutting the corners too large and although large corners definitely ensure your board is well covered, they can look quite clunky and not very elegant.

We set about trying to create the foolproof corner cutter and came up with these beautifully made brass corner cutters. They are produced in three sizes to fit the standard board thicknesses of 1.5, 2.3 & 3mm. I glue up my cloth, place my boards and spine piece then pop the corner cutter on the cloth against the board corner and slice it with my blade, repeating for each corner, then turn it in and make my beautiful, neat, perfect corners. Give it all a rub down and a tap and you are good to go!

The “Inner Corner Cutter” always confuses people, it is used to make the turn ins on the inside of boxes. Before gluing the cloth for the wall is cut to shape and folded down the inside of the walls. The corner cutter is used to trim the cloth that comes out from the corner to the floor or lid of a box on about a 45-degree angle from each abutting wall and overlaps each other by about 1mm. I know that sounds confusing so I will make another little video soon to demonstrate that.

I hope you enjoyed the video and that these little tips save you some time and heartache in making your beautiful books.